Cutting a 20in Diameter Circle out of Plexiglass

Learn how to cut a perfect 20-inch diameter circle from plexiglass with step-by-step methods, tools, and safety tips for clean, precise results.

Cutting a 20-inch diameter circle from a 1/16-inch or 1/8-inch thick plexiglass sheet is a challenging but achievable task with the right tools, techniques, and precautions. Plexiglass, a brand name for cell-cast acrylic, is valued for its clarity, durability, and versatility in projects like tabletops, windows, or custom displays. However, its brittle nature requires careful handling to avoid cracking, chipping, or melting during cutting. This guide provides a detailed, step-by-step approach to cutting a precise 20-inch circle, tailored for both DIY enthusiasts with limited tools and professionals with access to advanced equipment. We’ll explore multiple methods, tool specifications, safety tips, and finishing techniques to ensure a clean, polished result.

Understanding Plexiglass: Material Properties and Challenges

Plexiglass is a type of cell-cast acrylic, distinct from extruded acrylic due to its tougher surface, which resists scratches and impurities better. Its transparency and strength make it ideal for applications like the circular tabletop described in user projects, where a 20-inch diameter piece is needed, sometimes with a central hole for designs like stained glass vinyl inserts. However, cutting plexiglass poses challenges:

- Brittleness: Thin sheets (1/16″ to 1/8″) are prone to cracking if not properly supported or cut too aggressively.

- Melting Risk: High-speed cutting tools can generate heat, causing the material to melt and create rough edges.

- Vibration Sensitivity: Vibrations from tools like jigsaws can lead to chipping or uneven cuts.

- Precision Needs: A 20-inch circle demands accuracy, especially for aesthetic projects requiring smooth, polished edges.

To overcome these, you’ll need to select the appropriate tools, secure the material properly, and follow precise cutting techniques. Below, we outline the best methods based on available tools, including those mentioned by users (jigsaw, drill, hacksaw, box cutter) and advanced options like routers or laser cutters.

Tools and Materials Needed

Before diving into the methods, here’s a comprehensive list of tools and materials you’ll need, depending on the approach:

| Tool/Material | Purpose | Approx. Cost (USD) |

|---|---|---|

| Jigsaw (fine-tooth blade for plastics/metal) | Cutting curves, rough circle cuts | $30–$100 (tool); $5–$15 (blade) |

| Electric Drill (with 1/4″ and smaller bits) | Creating pilot holes for jigs or center points | $30–$80 |

| Hole Saw (1″ for center hole) | Cutting the central 1″ hole | $10–$25 |

| Scoring Tool (or box cutter) | Scoring for light etching or marking | $5–$15 |

| Router (with circle jig and carbide bit) | Precision circle cutting | $50–$150 (tool); $10–$30 (bit) |

| Bandsaw (fine-tooth blade) | Cutting large or thick sheets | $100–$500 |

| Dremel (with router bit) | Small-scale trimming or sanding | $30–$80 |

| Sandpaper (120–400 grit) | Smoothing edges post-cut | $5–$10 |

| Masking Tape | Protecting surface, reducing vibration | $3–$7 |

| Plywood/MDF (for jig/template) | Stabilizing plexiglass, guiding cuts | $10–$20 |

| Clamps | Securing material | $10–$30 |

| Safety Goggles/Gloves | Eye and hand protection | $5–$15 |

| Laser Cutter (optional) | Precision cutting (professional use) | $500–$5000 (or service fee: $20–$50) |

Note: Prices are approximate and based on common retail sources like Home Depot, Harbor Freight, or Amazon. For one-off projects, consider borrowing tools or using makerspace services to save costs.

Method 1: Jigsaw with Circle Jig

The jigsaw method, suggested by users like Porrthos and Seattle2Boston, is accessible for DIYers with limited tools. A jigsaw with a fine-tooth blade designed for plastics or metal can cut a 20-inch circle, but requires a jig to maintain precision.

Steps:

- Prepare the Workspace:

- Secure a flat workbench with ample space for a 24″x24″ plexiglass sheet.

- Place the plexiglass between two sheets of plywood or MDF to reduce vibration and prevent cracking. Clamp all layers tightly.

- Create a Circle Jig:

- Cut a piece of wood (e.g., 1″x2″x24″) to serve as a jig arm.

- Drill a small hole at one end of the wood for a nail or screw to act as the pivot point.

- Measure 10 inches (radius of a 20-inch circle) from the pivot hole and drill another hole for the jigsaw blade to pass through.

- Secure the pivot point to the center of the plexiglass with a nail or screw, ensuring it’s aligned with the desired circle center.

- Mark the Circle:

- Use a string and pencil or a compass to lightly mark a 20-inch diameter circle on masking tape applied to the plexiglass. This helps guide your cut and protects the surface.

- Cut the Circle:

- Equip the jigsaw with a fine-tooth blade (e.g., Bosch T101A for acrylic or metal).

- Insert the blade through the jig’s blade hole and start cutting slowly, rotating the plexiglass around the pivot point.

- Move steadily to avoid melting the plastic. Pause if the blade heats up.

- Drill the Center Hole:

- Use a 1-inch hole saw or spade bit on a drill to cut the central hole. Apply masking tape on both sides to prevent cracking, and drill slowly with light pressure.

- Finish the Edges:

- Sand the edges with 120-grit sandpaper, progressing to 400-grit for a smooth finish.

- Optionally, flame-polish the edges with a propane torch (practice on scrap first to avoid melting).

Pros:

- Affordable with basic tools.

- Suitable for thin plexiglass (1/16″–1/8″).

- Jig ensures consistent radius.

Cons:

- Risk of uneven cuts if the blade is too coarse or speed is too high.

- Requires careful setup to avoid vibration-induced cracks.

Method 2: Scoring and Snapping (Manual Method)

For those limited to hand tools like a box cutter, scoring is a low-cost option, though less precise for large circles. This method works better for straight lines but can be adapted with patience.

Steps:

- Mark the Circle:

- Apply masking tape to both sides of the plexiglass.

- Use a compass or a string tied to a nail (10-inch radius) to scribe a 20-inch diameter circle on the tape.

- Score the Circle:

- Use a sharp scoring tool or box cutter to lightly score along the marked circle. Repeat 8–10 times, deepening the score with each pass.

- Avoid excessive pressure to prevent cracking.

- Snap the Circle:

- Place the scored line over the edge of a table and gently press to snap the circle out. This may be challenging for a 20-inch circle due to its size.

- Drill the Center Hole:

- Use a 1-inch hole saw or drill bit, with masking tape on both sides, to cut the central hole.

- Smooth the Edges:

- Sand the edges with 120–400-grit sandpaper to remove roughness.

Pros:

- Minimal tools required.

- Low cost if you already own a box cutter.

Cons:

- Difficult to achieve a perfect circle due to manual scoring.

- High risk of cracking or uneven edges.

- Time-consuming for large diameters.

Method 3: Router with Circle Jig

A router with a circle jig, as recommended by users like ev3rm0r3 and Scott Gibbons, offers superior precision for a 20-inch circle. This method is ideal if you have access to a router and are comfortable with woodworking tools.

Steps:

- Create a Router Jig:

- Cut a piece of MDF or plywood (e.g., 24″x24″) as a base.

- Attach a pivot arm (wood or metal) to the router base, with a pivot point 10 inches from the router bit.

- Secure the pivot point to the plexiglass center with double-sided tape or a screw.

- Secure the Plexiglass:

- Sandwich the plexiglass between two MDF sheets to prevent vibration. Clamp securely.

- Cut the Circle:

- Use a carbide spiral bit (e.g., 1/4″ up-cut bit) to avoid melting the plastic.

- Set the router to a low speed and make shallow passes (1/32″ per pass) to cut the 20-inch circle.

- Rotate the router around the pivot point for a consistent cut.

- Drill the Center Hole:

- Use a 1-inch hole saw or drill bit with masking tape to cut the central hole.

- Finish the Edges:

- Sand with 120–400-grit sandpaper.

- Flame-polish with a propane torch for a glossy edge, keeping the flame 2–3 inches away and moving quickly.

Pros:

- Highly precise and clean cuts.

- Suitable for multiple circles in production settings.

- Polished edges with minimal sanding.

Cons:

- Requires a router and jig setup, which may be costly.

- Learning curve for router operation.

Method 4: Laser Cutting

Laser cutting, as suggested by users like madsci and euphoniousmonk, is the gold standard for precision and edge quality. It’s ideal for a 20-inch circle but requires access to a laser cutter, often found in makerspaces or professional shops.

Steps:

- Find a Laser Cutting Service:

- Check local makerspaces, libraries, or fabrication shops (e.g., TechShop). Services typically charge $20–$50 per hour.

- Alternatively, purchase a laser cutter like the Glowforge Plus ($2,500–$4,000) for frequent use.

- Prepare the Design:

- Create a CAD file (e.g., in Inkscape or AutoCAD) for a 20-inch circle with a 1-inch central hole.

- Specify the material as 1/16″ or 1/8″ acrylic and set laser parameters (e.g., 100% power, 5–10 mm/s speed for CO2 lasers).

- Cut the Circle:

- Place the plexiglass in the laser cutter, ensuring it’s flat and secured.

- Run the laser cutter, monitoring for proper ventilation to avoid fumes.

- Finish the Edges:

- Laser-cut edges are typically polished and require minimal sanding.

Pros:

- Extremely precise with polished edges.

- Fast for single or multiple cuts.

- No vibration or cracking risk.

Cons:

- Expensive equipment or service fees.

- Requires CAD knowledge and access to a laser cutter.

Method 5: Purchasing Pre-Cut Plexiglass

As noted by EdT, buying pre-cut 20-inch plexiglass circles from suppliers like Delvie’s Plastics can save time and effort. This is ideal for one-off projects or when tools are limited.

Steps:

- Contact a Supplier:

- Check suppliers like Delvie’s Plastics, TAP Plastics, or local hardware stores.

- Request a 20-inch diameter circle with a 1-inch central hole in 1/16″ or 1/8″ plexiglass. Prices typically range from $15–$50, depending on thickness.

- Specify Requirements:

- Confirm the material is cell-cast acrylic (Plexiglass) for durability.

- Request edge polishing if needed.

- Verify and Install:

- Inspect the delivered circle for accuracy.

- Use the pre-cut piece directly in your project.

Pros:

- No cutting required, saving time and tools.

- Professional-grade precision.

- Cost-effective for small quantities.

Cons:

- Limited customization for complex designs.

- Shipping costs may apply.

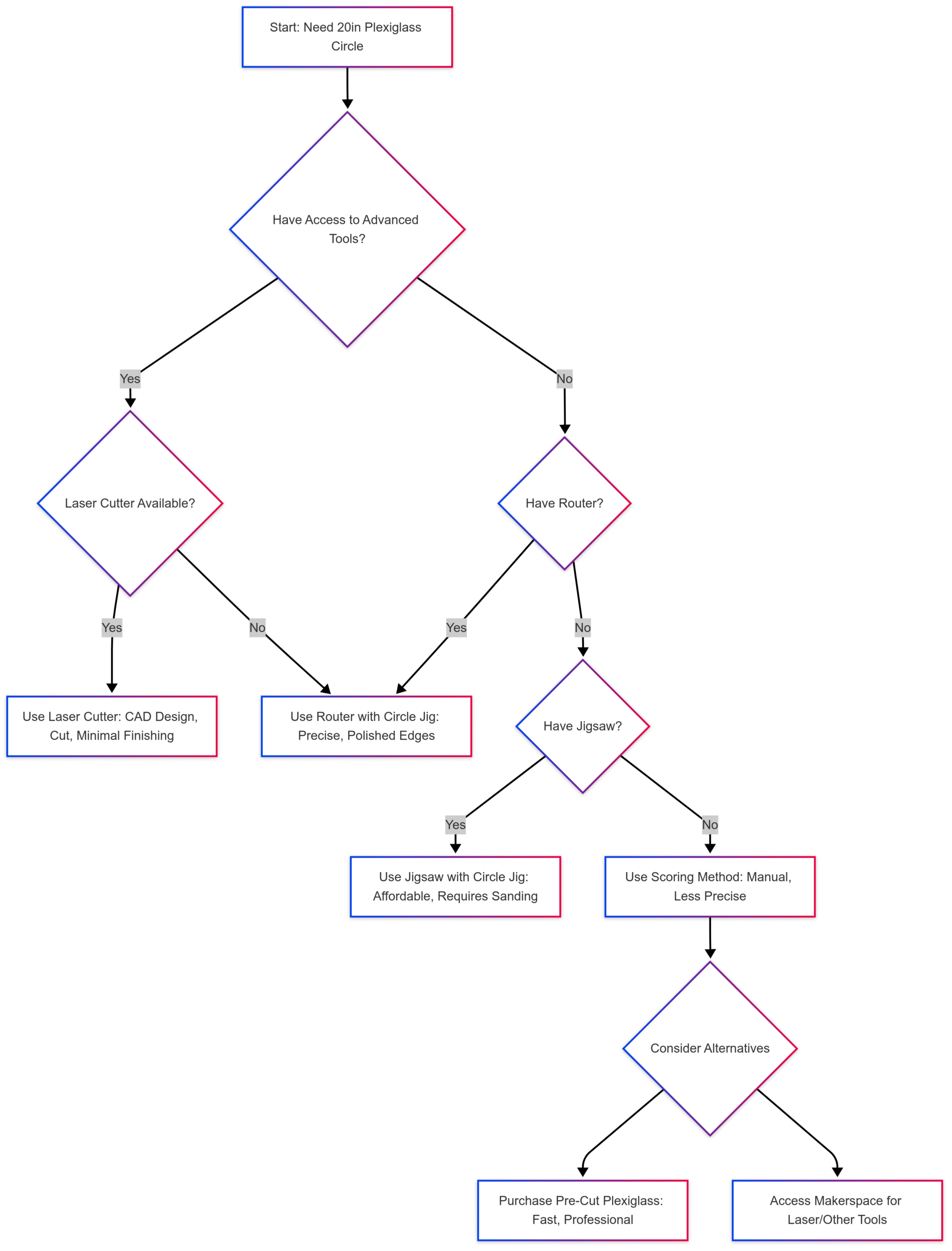

Chart: Workflow for Cutting a 20-Inch Plexiglass Circle

Below is a flowchart outlining the decision-making process for choosing the best cutting method based on available tools and project needs.

Safety Tips for Cutting Plexiglass

- Wear Protective Gear: Always use safety goggles and gloves to protect against flying shards and sharp edges.

- Secure the Material: Clamp plexiglass firmly to prevent vibration, which can cause cracks.

- Use Masking Tape: Apply tape to both sides to reduce chipping and provide a marking surface.

- Cut Slowly: Avoid overheating the material, which can cause melting or rough edges.

- Ventilate the Area: Especially with laser cutting, ensure proper ventilation to avoid inhaling acrylic fumes.

Finishing Techniques

After cutting, the edges of the 20-inch circle may need refinement:

- Sanding: Start with 120-grit sandpaper to remove rough spots, then progress to 400-grit for smoothness.

- Flame Polishing: Use a propane torch to lightly heat the edges, creating a glossy finish. Practice on scrap to perfect the technique.

- Buffing: Use a polishing compound and a soft cloth for a crystal-clear edge, especially for aesthetic projects like tabletops.

Comparison of Methods

| Method | Precision | Cost | Time | Best For |

|---|---|---|---|---|

| Jigsaw with Jig | Moderate | Low ($10–$50) | 1–2 hours | DIYers with basic tools |

| Scoring | Low | Very Low ($5–$15) | 2–3 hours | Manual, small projects |

| Router with Jig | High | Moderate ($50–$150) | 1–2 hours | Precise, repeatable cuts |

| Laser Cutting | Very High | High ($20–$5000) | 30 min–1 hour | Professional, polished results |

| Pre-Cut Purchase | Very High | Moderate ($15–$50) | Immediate | One-off projects, no tools |

Real-World Application: User Project Example

One user described a project involving a circular ottoman with a 20-inch plexiglass tabletop, sandwiching a vinyl stained glass design. This requires two identical 20-inch circles with a central hole. The router or laser cutting methods are ideal here, as they provide the precision needed for a polished, professional look. The jigsaw method could work with careful execution and sanding, but the scoring method is less reliable due to the large diameter and aesthetic requirements.

Troubleshooting Common Issues

- Cracking: Ensure the plexiglass is clamped securely and cut slowly. Use polycarbonate (Lexan) if cracking persists, as it’s less brittle.

- Melting: Reduce tool speed and make shallow passes. Use blades/bits designed for plastics.

- Uneven Edges: Use a jig for consistent cuts and sand thoroughly post-cutting.

- Vibration: Sandwich the plexiglass between plywood/MDF to stabilize it during cutting.

Where to Buy Tools and Materials

- Plexiglass: Home Depot, Lowe’s, TAP Plastics, or Delvie’s Plastics. A 24″x24″x1/8″ sheet costs ~$20–$40.

- Jigsaw Blades: Bosch T101A or T118A (for plastics/metal) at hardware stores (~$5–$15).

- Hole Saws: Harbor Freight or Amazon (~$10–$25 for 1-inch).

- Routers: Home Depot or Amazon (e.g., Bosch Colt, ~$100).

- Laser Cutting Services: Local makerspaces or online services like Ponoko.

Conclusion

Cutting a 20-inch diameter circle from plexiglass is achievable with various methods, depending on your tools and budget. For DIYers with a jigsaw and drill, a circle jig offers a cost-effective solution, though it requires careful execution. A router provides higher precision, while laser cutting delivers professional-grade results at a higher cost. For one-off projects, purchasing pre-cut plexiglass may be the easiest option. By following the outlined steps, using proper safety measures, and finishing the edges carefully, you can achieve a clean, precise circle for your project, whether it’s a tabletop, display, or custom craft.

Please share this Cutting a 20in Diameter Circle out of Plexiglass your friends and do a comment below about your feedback.

We will meet you on next article.

Until you can read, Can fire pit rocks explode?