Cold Water Not Working on Washing Machine

Troubleshoot and fix cold water issues in your washing machine. Learn causes, solutions, and maintenance tips for top and front-load washers.

Washing machines are essential household appliances, but when the cold water supply fails, it can disrupt laundry routines and lead to frustration. Whether you own a top-loading or front-loading washing machine, a lack of cold water flow can stem from various issues, such as clogged filters, faulty inlet valves, or inadequate water pressure. This comprehensive guide explores the reasons behind cold water not working in washing machines, provides step-by-step troubleshooting methods, and offers preventive maintenance tips to keep your appliance running smoothly. With insights from real-world scenarios and expert advice, this article is your go-to resource for resolving cold water issues effectively.

Understanding Washing Machine Water Supply Systems

Washing machines rely on a water supply system to fill the drum with hot and cold water for washing and rinsing cycles. The system includes fill hoses, water inlet valves, and often mesh filters to prevent sediment from entering the machine. The configuration varies between top-loading and front-loading washing machines:

- Top-Loading Washing Machines: Many top-loaders, such as certain Samsung models, have dual water supply inlets for hot and cold water, as they lack internal heaters. However, some models use only a cold water supply, relying on external hot water sources for specific riguing cycles.

- Front-Loading Washing Machines: Most front-loaders, like Samsung’s, typically have a single water inlet because they feature an internal heater to adjust water temperature. Cold water is still essential for specific cycles, such as rinsing.

Understanding your machine’s water supply setup is crucial for diagnosing issues effectively.

Common Reasons for Cold Water Not Working

When cold water fails to flow into the washing machine, several factors could be at play. Here are the primary culprits:

- Kinked or Blocked Hoses: Fill hoses may be bent, twisted, or not fully connected, restricting water flow.

- Inadequate Water Pressure: Low water pressure from the household supply can prevent adequate water flow.

- Clogged Mesh Filter: Sediment or debris in the mesh filter at the hose’s connection point can block water flow.

- Faulty Water Inlet Valve: The electrically operated valve controlling water entry may have a defective cold water solenoid.

- Control Board or Temperature Switch Issues: Problems with the machine’s control board or temperature selector switch can prevent the cold water valve from activating.

Each of these issues requires specific troubleshooting steps, which we’ll cover in detail.

Troubleshooting Cold Water Issues: Step-by-Step Guide

Resolving cold water problems involves systematically checking each potential cause. Follow these steps to diagnose and fix the issue.

Step 1: Inspect Hoses and Faucets

Kinked or improperly connected hoses are a common cause of water flow issues. To check:

- Ensure faucets are fully open: Verify that the cold water tap is turned on completely.

- Check for kinks: Examine the cold water hose for bends or twists that could restrict flow. Straighten any kinks.

- Test hose flow: Disconnect the hose from the washing machine, place the end in a bucket, and turn on the faucet. Strong water flow indicates the household supply is adequate. If the flow is weak, check for blockages or contact a plumber to assess household water pressure.

Step 2: Clean the Mesh Filter

The mesh filter, located where the hose connects to the faucet or machine, prevents sediment from entering the water inlet valve. Over time, debris can accumulate and block water flow. To clean it:

- Turn off the water supply and unplug the washing machine for safety.

- Use pliers to gently remove the mesh filter from the hose or inlet valve.

- Rinse the filter under running water to remove sediment. For stubborn debris, soak it in vinegar or use a soft brush.

- Reinstall the filter, reconnect the hose, and turn the water supply back on.

- Check for leaks around the connection points.

Step 3: Test the Water Inlet Valve

The water inlet valve, an electrically operated component, controls the flow of hot and cold water into the machine. A faulty cold water solenoid can prevent water from entering during specific cycles. To test the valve:

- Use a multimeter: Disconnect the power to the machine. Set a digital multimeter (DMM) to the Ohmmeter function and test the cold water solenoid for continuity. A reading of infinite resistance or no continuity suggests a defective solenoid.

- Compare with hot water solenoid: If the hot water solenoid works but the cold water solenoid shows no continuity, the valve may need replacement.

Replacement water inlet valves vary by brand and model. For example:

- Whirlpool WP21001827 Valve: Approximately $50–$80, compatible with select Whirlpool models.

- GE WH12X10498 Rotary Switch: Around $20–$40, used in models like GTWP1800DOWW.

Always check your machine’s model number to ensure compatibility when ordering parts.

Step 4: Check the Temperature Switch or Control Board

If the hoses, filters, and inlet valve are functioning, the issue may lie with the temperature selector switch or control board. These components signal the inlet valve to open or close. A malfunction can prevent the cold water solenoid from activating.

- Test the temperature switch: For models like the GE GTWP1800DOWW, the rotary switch (Part #WH12X10498, ~$30) can be tested with a multimeter for continuity. A lack of continuity indicates a need for replacement.

- Inspect the control board: A faulty control board may fail to send power to the cold water solenoid. This is more complex to diagnose and often requires professional assistance.

Step 5: Verify Cycle-Specific Behavior

Some washing machines, especially top-loaders, use cold water only during specific cycles (e.g., rinsing). Refer to your owner’s manual to confirm whether the machine is operating as designed. For instance, an Amana washer may alternate hot and cold water to balance temperatures, which could be mistaken for a fault.

Real-World Case Studies

To illustrate these issues, let’s examine real-world examples from user experiences:

Case 1: 15-Year-Old Amana Washer

A user reported that their Amana washer suddenly lost cold water pressure, with only a trickle during the rinse cycle. After cleaning the mesh filter and replacing the inlet valve, the issue persisted. However, switching from a hot to a cold setting mid-cycle restored normal flow. This suggests a potential issue with the temperature switch or control board, as the valve functioned when triggered differently.

Solution: Testing the temperature switch with a multimeter and replacing it resolved the issue. The user opted for a DIY replacement, costing approximately $30 for the part.

Case 2: Simpson Eziset 6kg Top-Loader

Another user noted that their Simpson top-loader had hot water flow but no cold water. After verifying that the cold water tap was on and the hose was clear, the issue pointed to a faulty inlet valve or control board.

Solution: Replacing the inlet valve, costing $60–$100 depending on the model, was recommended. The user confirmed water was reaching the machine, indicating a defective valve.

Case 3: New Paykel Washer

A customer with a new Paykel washer reported no cold water during a test wash, despite strong water flow at the hose. The issue was traced to a defective inlet valve, a rare but possible occurrence even in new machines.

Solution: The user arranged for a service replacement of the inlet valve under warranty, avoiding out-of-pocket costs.

Preventive Maintenance Tips

To avoid future cold water issues, regular maintenance is key. Here are actionable tips:

- Clean mesh filters every 6–12 months: Regular cleaning prevents sediment buildup.

- Inspect hoses annually: Check for kinks, wear, or leaks and replace hoses every 5–7 years.

- Monitor water pressure: Ensure household water pressure is adequate (typically 20–80 psi for most machines).

- Schedule professional servicing: For complex issues like control board failures, contact a certified technician.

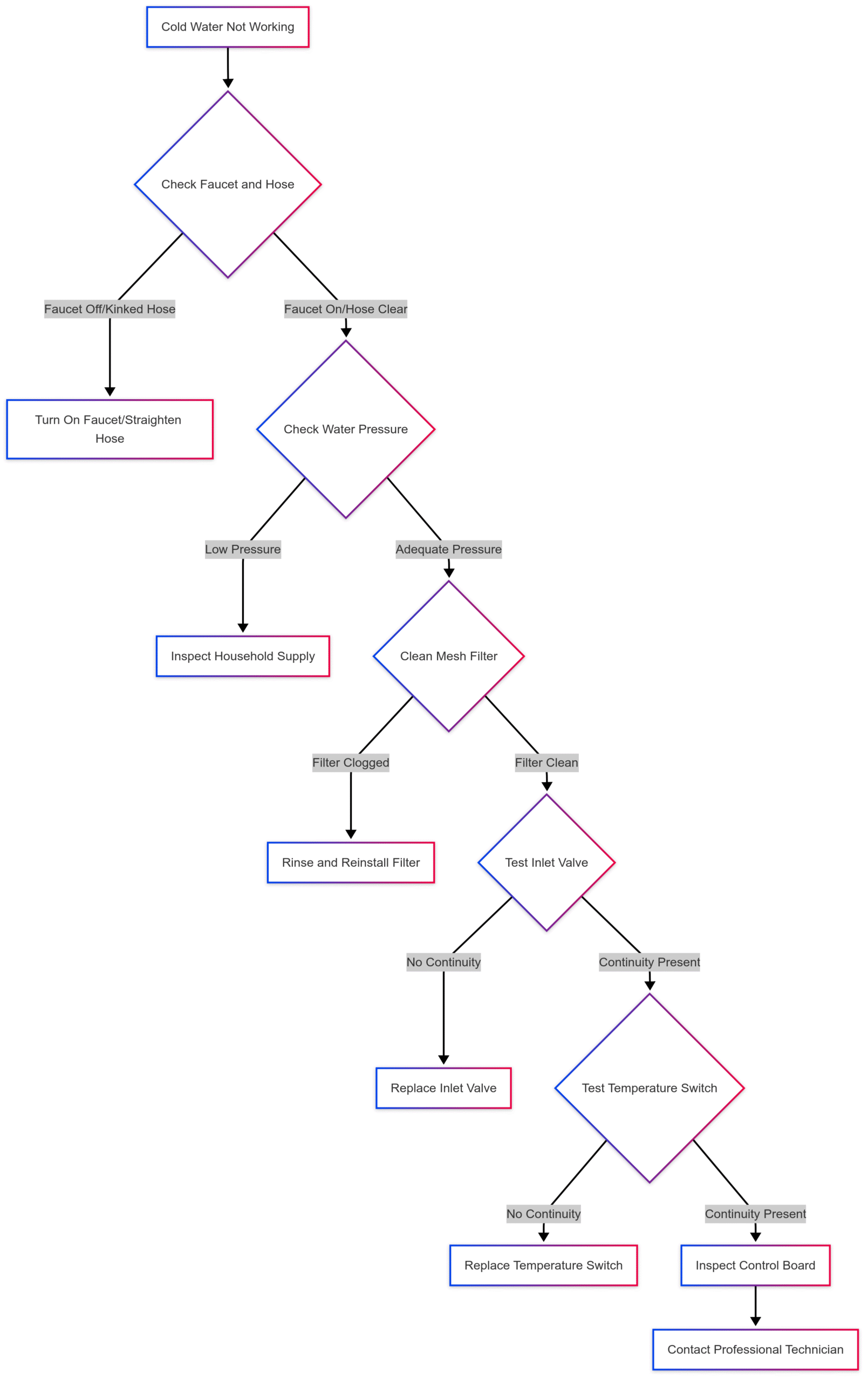

Visualizing the Troubleshooting Process

To clarify the troubleshooting steps, here’s a flowchart illustrating the diagnostic process:

This flowchart helps visualize the logical progression of diagnosing cold water issues, ensuring no step is overlooked.

Cost Breakdown for Common Repairs

| Component | Estimated Cost (USD) | DIY Difficulty | Notes |

|---|---|---|---|

| Mesh Filter Cleaning | $0–$10 (cleaning supplies) | Easy | Requires basic tools (pliers, brush) and minimal time. |

| Water Inlet Valve Replacement | $50–$100 | Moderate | Requires model-specific part; check compatibility with manufacturer. |

| Temperature Switch Replacement | $20–$40 | Moderate | Multimeter needed for testing; replacement is straightforward. |

| Professional Service Call | $100–$300 | N/A | Costs vary by region and complexity; includes diagnosis and labor. |

Note: Prices are approximate and depend on the washing machine brand, model, and region. Always verify part compatibility using your machine’s model number.

When to Call a Professional

While many cold water issues can be resolved with DIY methods, certain scenarios warrant professional help:

- Persistent issues after troubleshooting: If hoses, filters, and valves are functional, a control board or wiring issue may require expert diagnosis.

- Lack of tools or expertise: Testing electrical components like solenoids or switches requires a multimeter and basic electrical knowledge.

- Warranty considerations: For new machines, contact the manufacturer or retailer to avoid voiding the warranty.

For residents in areas like Las Vegas or Clark County, services like Paul’s Washer and Dryer Repair offer on-site repairs, eliminating the need to move heavy appliances. Scheduling a technician can cost $100–$300, depending on the issue’s complexity.

Choosing Replacement Parts

When replacing parts, ensure compatibility with your washing machine’s make and model. Common brands like Whirlpool, GE, and Samsung have specific part numbers (e.g., Whirlpool WP21001827, GE WH12X10498). Purchase from reputable suppliers like AppliancePartsPros.com or PartsDr.com, and expect to pay:

- Water Inlet Valve: $50–$100

- Temperature Switch: $20–$40

- Control Board: $100–$200 (varies widely by model)

Always cross-reference part numbers with your owner’s manual or manufacturer’s website to avoid errors.

Conclusion

Cold water not working in a washing machine can stem from simple issues like kinked hoses or clogged filters to more complex problems like faulty inlet valves or control boards. By following a systematic troubleshooting process—checking hoses, cleaning filters, testing valves, and inspecting switches—you can often resolve the issue without professional help. Regular maintenance, such as cleaning filters and inspecting hoses, can prevent future problems and extend your machine’s lifespan. For complex issues or new appliances under warranty, don’t hesitate to contact a professional technician. With the right approach, your washing machine will be back to delivering clean clothes with the perfect water temperature in no time.

Please share this Cold Water Not Working on Washing Machine your friends and do a comment below about your feedback.

We will meet you on next article.

Until you can read, Cotton Cycle Vs Permanent Press Cycle On Washer Machines